OUR BRAND NEW

PALLETIZER

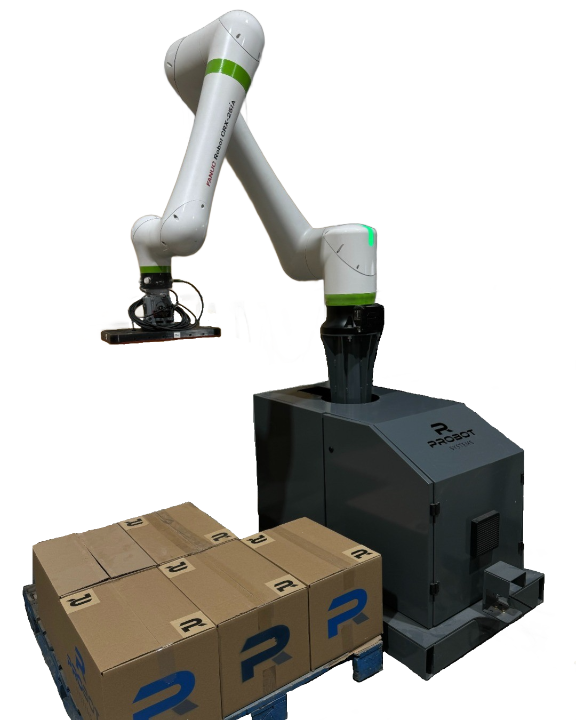

Revolutionize your production line with our palletizer: an innovative solution that combines efficiency, precision and safety.

ABOUT

Discover our brand-new collaborative robotic palletizer, designed to revolutionize production processes in the food & beverage, pharmaceutical and manufacturing sectors through advanced system automation.

Food & beverage: Guarantee the quality and safety of your products with precise, hygienic palletizing. Our palletizers can handle a wide variety of product shapes and sizes, guaranteeing stable stacking and maximum efficiency, and offering a solution to labor shortages.

Pharmaceutical industry: Benefit from exceptional precision and rigorous compliance with safety standards. Our palletizers handle sensitive products with care, reducing the risk of contamination and errors, while increasing production speed and efficiency, thanks to state-of-the-art automation systems.

Manufacturing industry: Increase productivity and reduce operating costs with our high-performance palletizer. Adaptable and easy to reprogram, it integrates perfectly into various production configurations, enabling rapid changeovers and process optimization, and meeting the challenges of labor shortages with innovative robotics.

Our experts are ready to help you maximize the efficiency of your production line and achieve your growth objectives.

FEATURES

Maximum Payload

Our palletizer is designed to handle loads of up to 30 kg, including the griper, making it ideal for a wide variety of industrial applications. Thanks to its robustness and precision, it can efficiently handle products of different sizes and weights without compromising pallet safety or stability.

Maximum Pallet Height

Our collaborative robot palletizer can handle pallets up to a maximum height of 2 200 mm. This feature allows you to optimize the use of space in your warehouse or production area by stacking products efficiently.

Maximum Speed

Our palletizer is capable of reaching a maximum speed of 7 cycles per minute, depending on the load.

Higher speeds may require additional

additional safety measures.

This high performance enables you to optimize production lines by reducing cycle times and increasing the overall efficiency of your palletizing process.

Robot brand

Our FANUC robots, renowned worldwide for their reliability and performance, are at the cutting edge of industrial automation. Thanks to their advanced technology and robustness, FANUC robots ensure maximum productivity and seamless integration into your production processes.

See the list of partners below for an overview of our suppliers and partners.

Type of load

We can easily adapt to your projects. Our palletizers can handle a wide range of loads, including boxes, bags, pharmaceutical jars, pallets and more.

Other features

FANUC offers 8 years maintenance-free.

100% proven industrial reliability.

NSF H1 food-grade grease.

USDA-compliant white epoxy coating.

*All these features depend on your project. We can offer you a customized robot for your specific project.

YOUR NEEDS, OUR COMMITMENT

1-day installation

Thanks to our expertise, we guarantee a fast and efficient installation in as little as 1 day. Minimize downtime and start optimizing your production immediately.

Labor shortage

Reduce the impact of labor shortages with our innovative palletizer, designed to automate your processes and optimize your production.

You’ll be able to reassign employees who used to perform these repetitive tasks.

Footprint

No need to rearrange your workspace: our palletizer occupies the same surface area as an average-sized human.

Simplicity and efficiency: Quick and intuitive to use

Our palletizer is designed to be simple and intuitive to use: learn quickly without the need for specific qualifications, and optimize your production from day one.

Enhanced safety

Designed to work alongside human operators, it minimizes the risk of accidents thanks to integrated sensors and safety systems.

Fast return on investment

Thanks to its high productivity and low maintenance costs, it offers a rapid return on investment.

These advantages make our new collaborative robot palletizer an ideal solution for improving the efficiency, safety and profitability of palletizing processes, particularly in the food & beverage, pharmaceutical and manufacturing industries.

OUR EXPERTISE

FAQ

Our palletizer offers several advantages over traditional models. It improves operational efficiency thanks to flexible programming and advanced automation, enabling rapid production changeovers and adaptability to your company’s changing needs. What’s more, our palletizer reduces the risk of accidents by working safely alongside operators, while offering superior precision in load placement. Finally, it optimizes space and reduces labor costs thanks to intelligent pallet management and simplified maintenance.

Robots, especially collaborative robots (cobots), enhance business efficiency by taking over non-value-added tasks. These automated systems handle these tasks more quickly and consistently since robots do not require rest periods and can operate continuously. This frees up the workforce to perform value-generating tasks, optimizing human resources.

This automation of systems brings several significant advantages:

- Improved production times: By eliminating human interruptions and variations, robots accelerate production cycles, thereby increasing overall output.

- Reduction in labor costs: Automating repetitive and non-value-added tasks allows companies to reduce their labor needs, lowering wage costs and associated expenses.

- Decreased health and safety costs: By taking on dangerous or physically demanding tasks, robots reduce the risk of injuries and occupational illnesses, leading to long-term savings in health and safety.

- Consistent and reliable production: Robots maintain a constant and predictable performance, minimizing errors and defects in production, which improves the quality of final products.

By integrating industrial robotics and automation solutions, businesses can transform their operations, increase efficiency, and significantly reduce costs. Contact us to discover how our collaborative robots and automated systems can optimize your production processes and generate added value for your company.

In the food industry, robots play a crucial role in a wide range of tasks, enhancing efficiency, precision, and safety. Their involvement spans various stages of production, including inspection, sorting, handling, packaging, and cleaning. This automation of systems is essential for maintaining high standards and meeting the demands of a competitive market.

By integrating robots and collaborative robots (cobots) into these operations, the food industry can achieve significant improvements:

- Inspection and Sorting: Robots equipped with advanced vision systems can inspect and sort food products with unparalleled accuracy, ensuring quality and consistency.

- Handling and Packaging: Automating handling and packaging reduces human errors, speeds up the process, and maintains hygiene standards, which are crucial in the food industry.

- Cleaning: Robots can perform cleaning tasks in production facilities, ensuring thorough sanitation and reducing the risk of contamination.

- Agricultural Automation: In agriculture, robots monitor crop health, manage animal feeding schedules, automate milking processes, collect eggs, and assist in harvesting, thereby increasing productivity and reducing labor costs.

By implementing robotic and automation solutions, the food industry can enhance operational efficiency, ensure consistent product quality, and maintain stringent health and safety standards. Contact us to learn more about how our robots and automated systems can revolutionize your food production processes.

Robots in packaging are capable of performing a wide range of tasks such as opening, transporting, filling, palletizing, sealing, labeling, and coding of products. They are particularly adept at case packing operations and can handle secondary packaging tasks, such as printing designs on the backs of boxes.

The objectives of industrial process automation encompass several essential aspects:

Enhancement of Workforce Productivity: Automation aims to free workers from repetitive, non-value-added tasks, enabling them to focus on higher-value activities, thus increasing overall efficiency and productivity.

Reduction of Overall Costs: By automating processes, companies can cut labor costs, minimize errors and defects, optimize resource utilization, and streamline operations, resulting in significant long-term savings.

Improvement of Product Quality: Automation ensures more consistent and precise production, reducing variations and defects, resulting in higher-quality end products and increased customer satisfaction.

Extension of Equipment Lifespan: By maintaining efficient and regular use of equipment, automation helps prolong their operational lifespan, thus optimizing capital investments.

Savings on Consumables and Raw Materials: Through more efficient use of raw materials and consumables, automation reduces waste and losses, leading to substantial cost savings.

Enhancement of Production Operation Safety: By eliminating hazardous and repetitive tasks, automation helps create a safer work environment, reducing the risks of accidents and injuries for workers.

By pursuing these objectives, industrial automation offers significant benefits to companies, enabling them to streamline operations, enhance competitiveness, and thrive in an ever-evolving business environment. Contact us to discover how our automation solutions can meet your specific needs and transform your business.

Our palletizer can be seamlessly and efficiently integrated into existing or new production lines. Thanks to its flexible design and adaptive programming, it adapts easily to your site’s specific configurations and requirements. Our experts work closely with your team to plan and execute the integration, minimizing operational disruption and maximizing production line efficiency. Whether you’re upgrading an existing line or installing a new system, our palletizer offers a tailor-made solution to meet your palletizing needs.

For a personalized consultation or to speak with one of our experts about our palletizer, you can contact us via the information provided in the “contact information” section of our website. You can reach us directly by telephone or e-mail. These are the most effective means of communication for answering your specific questions and scheduling a meeting at your convenience.

You can also click on “Talk to an expert” or “Contact us” and fill the form. This will allows us to have a bit more informations abour your situations. Then we will enter in contact with you shortly.

The expected service life of our palletizer is 20 years. The safety components of the industry are designed to ensure that the robots do not exceed this lifespan.

At that point, we encourage you to contact us, and we will be delighted to provide you with our latest technological advancements.

Our robot is designed to operate reliably and efficiently with minimum initial maintenance. FANUC offers 8 years of maintenance-free service.

For preventive or corrective maintenance, as well as parts replacement, our maintenance and support service is available. Our specialized technicians are ready to intervene to ensure that your robot runs at peak performance. Please do not hesitate to contact us for technical assistance or to schedule maintenance.

CONTACT INFORMATION

- Web site : www.probotsystems.com

- info@probotsystems.com

- +1 (418) 948-0909

- 8895 rue des Cordiers, suite 300, Lévis (QC) G6Y 0K5 Canada