Industrial Maintenance

Is your company ready to maximize its operational efficiency?

We take care of your industrial maintenance, you benefit from the results.

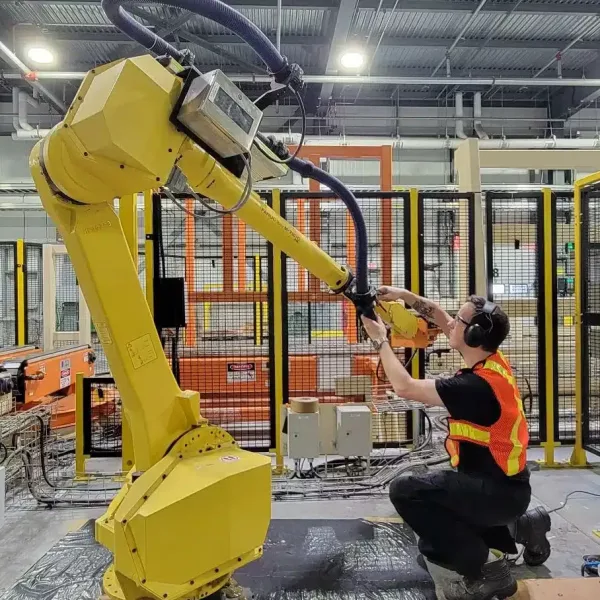

You can also entrust us with the annual and/or preventive industrial maintenance of your robots. Preventive maintenance helps improve your robots’ performance, ensuring optimum productivity.

When you entrust us with this mandate, you can rest assured that your robots are operating at full capacity, and that their lifespan will be optimized.

Industrial Maintenance Services

- Annual maintenance of robot(s) including:

- Grease change

- Battery change

- General visual and audible inspection of components

- Cleaning and lubricating joints

- Cooling system cleaning and filter replacement

- Testing and adjusting braking system

- Preventive maintenance

- Training for maintenance employees and supervisors

Probot performs comprehensive functional tests to ensure that the robot meets all specifications.

Regular preventive maintenance is crucial for robots, whether they are collaborative robots or automated systems, as it helps to prevent breakdowns and malfunctions of parts and components. Proper maintenance ensures that your robots operate optimally and extends their lifespan while maintaining the continuity and efficiency of your production.

Without regular preventive maintenance, you risk encountering various issues, such as:

- Position deviation: The robot may operate outside of the intended parameters, resulting in precision errors that affect the quality of the final product.

- Premature component wear: The lack of maintenance can accelerate the wear of critical parts, increasing the risk of sudden and costly breakdowns.

- Production interruptions: Unexpected breakdowns can lead to production stoppages, severely impacting productivity and delivery deadlines.

- Compromised safety: Faulty robots can pose safety risks to workers, especially in environments where they interact directly with humans.

By implementing industrial maintenance routines, you ensure the reliability and performance of your collaborative robots and automated systems. This includes regular inspections, replacement of worn parts, and adjustments to keep the robots in perfect working condition.

Investing in preventive maintenance not only minimizes the risk of breakdowns but also improves overall production efficiency, reduces long-term costs, and ensures a safe working environment. Contact us to learn more about our industrial maintenance services and how we can help you keep your robots in top shape.